Up to six total, probably stopping here.

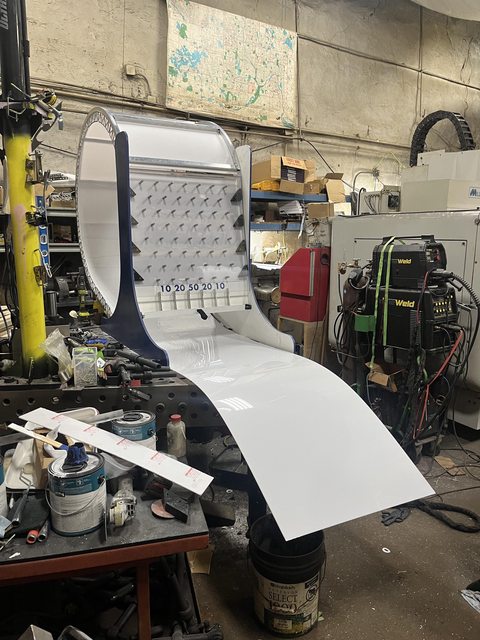

Imperfections galore. Need to sand the back where the type 1 sits into the type 2 so they'll mate together better. Three of the type 1 display section won't close with the rotary dial. One of the type 1 bottom sections is loose and will fall out.

Tempted to go to harbor freight and buy one of those hard cases with foam to make a storage box for them, but that's $40 of case for $15 of plastic.

Tried finding a design for a case to assemble that is larger than the print bed, but haven't.